Bamboo processing equipment assist in the production of bamboo merchandise. Bamboo is especially useful for house-produced items and objects like bamboo baskets, paper cups and bamboo vases etc. Bamboo can also be used for earning bamboo home furnishings. This can be an eco-welcoming content that may be fast attaining recognition all around the environment.

Bamboo creation will involve the mechanical processing of turning bamboo fibers into thread, yarn, and bamboo blades. Soon after this, these merchandise is often even further utilized for various functions. Bamboo fiber is principally utilized for generating dresses, sweaters and bed sheets and so forth. Bamboo blades are used for sawing wood and creating paper and cardboards. All of these merchandise are geared up with aid of a Bamboo Machine.

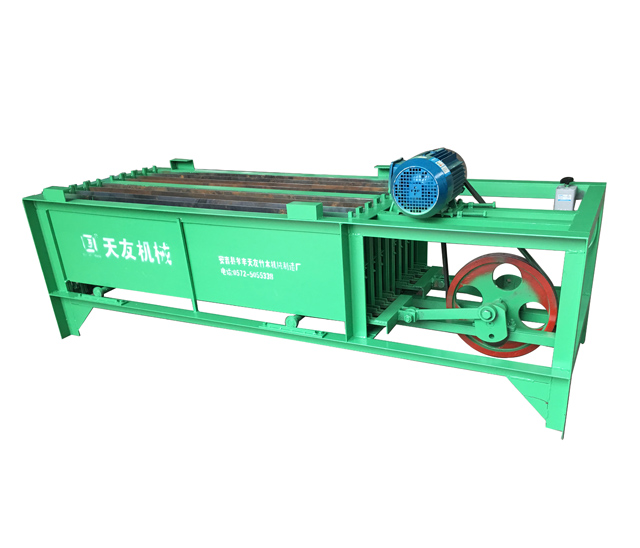

The Bamboo Equipment is split into two sorts particularly, the immediate and indirect Bamboo Device. The direct Bamboo Device features a cutter head as well as a conveyor. Bamboo fabric is fed in the conveyor and onto the cutter head. As the Bamboo material passes in the cutter head it is actually Slice into sought after dimensions. Bamboo strips of different thicknesses is usually bought from any Bamboo vendor.

The second form of Bamboo Equipment is the oblique Bamboo Machine. This machine is very similar to the utility design of Bamboo but with no bamboo fabric. The cuttings come from possibly a belt or from a knife rest. Bamboo cloth is handed in the knife rest and on to your belt, which can be then run more than a pulley. When the belt passes more than the knife relaxation then it slices the Bamboo into the specified dimensions.

The 3rd sort of Bamboo Device would be the conveying roller steady feed formula is Lower open up the bamboo equipment by sliding the knife rest in the equipment. The thin bamboo tube is put inside the device as well as knife rests are slid in to the tube. Bamboo strips of different thicknesses are fed in the equipment with the knife relaxation. Bamboo material is fed in the tube and onto the belt, which happen to be then operate above a pulley. Bamboo strips of various thicknesses are then sliced on to the belt from the belt as it really is rolled throughout the belt. This Bamboo Equipment is more well-liked compared to utility product of Bamboo.

Bamboo slabs and blocks are fed into your 4 aspect planer by thin belts. Bamboo strips along with the blocks are sliced into the four aspect planer because of the exterior knot system. This Bamboo Machine is definitely the quickest Bamboo earning equipment arrange. The 4 side planer plus the exterior knot mechanism slice the Bamboo into Bamboo strips and Bamboo blocks evenly and without slippage.

The fourth type of Bamboo machine may be the 4 side planer Bamboo cutter. This Bamboo equipment differs from your three varieties of Bamboo described over. It has a front conclusion feed cutter along with a back conclude slimmer cutter. Bamboo slabs and blocks are fed into your front end with the Bamboo cutter by thin belts. Bamboo fabric is handed throughout the entrance conclusion in the Bamboo cutter, while the fiber slabs and blocks are sliced on to the belt via the slimmer system.

The last Bamboo Device is easily the most interesting Bamboo device because it brings together the many Bamboo Devices into just one Bamboo splitter. This Bamboo splitter has 4 reducing mechanisms that run concurrently. The main system cuts with the skinny bamboo strips. Bamboo cloth passes with the chopping system as well as the fiber strip is Lower into Bamboo strips according to the dimension with the equipment's letterhead. Then, the remaining Bamboo materials is passed via a conveying roller as well as Bamboo fiber is gathered while in the entrance conclusion with the acquiring unit.

Bamboo production is increasing at an incredible charge in the final ten years. Bamboo production is often a strategy of collecting and chopping Bamboo into many items such as Bamboo Shoe, Bamboo Flooring, Bamboo Furnishings, Bamboo Mattress, Bamboo Stool, Bamboo Chair and Bamboo Panels. Bamboo has several advantages about regular lumber trees that are additional environmentally liable. As Bamboo grows a lot quicker than trees it will not be In a nutshell offer and Bamboo merchandise might be readily available.

To build Bamboo merchandise there are two output strategies employed, either from the utilization of the Compressed Air Mould or even a Dry Sinking or Vacuum Mould. A standard Bamboo Board production generation line approach begins using a higher-velocity horizontal cross-Slice noticed reducing a brief duration of Bamboo fiber plank. The Bamboo board is placed on a drying System that circulates water that contains silica that can help dampness evaporate with the Bamboo plank and force out the shrinking edges of Bamboo fiber plank. Bamboo is then sliced with hand knives into uniform lengths and the pieces are pulled via an assortment of sawing motions. Several different grinding tools and grinding wheels are utilized to further more polish the surfaces of Bamboo pieces.

Just after Bamboo boards are cut and trimmed to ideal lengths, They may be then laid horizontally to become Bamboo Shoe or Bamboo Flooring. From the Bamboo Flooring producing line, a Bamboo Shoe is prepared by passing two circular observed blades over the boards to produce a cross-hatched sample. This sample is what varieties the Bamboo Flooring panels. A number of grinding instruments and grinding wheels are utilized to additional polish the surfaces from the Bamboo Flooring panels. As soon as the Bamboo Shoe/Bamboo Flooring is finished the Bamboo is packaged in its respective strips plus the strips are bundled collectively.

To aid in Bamboo Door-plate manufacture; a thin, but sturdy, bamboo wood is Reduce into manageable measurements. The Slash bamboo Wooden is then put on a heated stainless steel floor that's higher than a water reservoir. The heated bamboo wood doorway-plate substance is positioned into the heating mechanism. This Bamboo Door-plate content is then permitted to treatment to attain its distinct humidity content. The moment cured, the Bamboo door-plate is then inserted in the utility product thus forming the Bamboo doorway-plate together with Bamboo Flooring into its respective utility types.

Immediately after Bamboo boards are shaped into Bamboo doorway-plate and Bamboo flooring, the Bamboo door-plate and Bamboo flooring are then pressed alongside one another into an individual Bamboo molding unit. The Bamboo molding unit is then remaining to dry right until it yields into a firm and reliable Bamboo panel. Once the Bamboo panel has dried into a firm and sound condition, the Bamboo molding device is pulled with the drying Bamboo panel. The Bamboo molding unit is then still left to dry on its own for a further eighteen several hours. This Bamboo molding is then applied to develop the Bamboo door-panels that comprise the utility design of your Bamboo solution. After the Bamboo door-panels have dried to your company and sound condition the Bamboo door-panels are once again pressurized into their respective utility types.

Inside the Bamboo door-plate and Bamboo flooring application, Bamboo pieces are milled in accordance Using the utility product that They are going to be used in. Once the Bamboo components are milled to the suitable utility model the Bamboo producing line is going to be using, the Bamboo supplies are then pressed into their respective moldings. The presses accustomed to press the Bamboo materials into their moldings are often called "expander push" procedures. Pressurizing the Bamboo materials into their moldings employing these Expander press approaches generate Bamboo panels which are constant in measurement, steady in color and constant in form. This regular Bamboo size, coloration and form all over all Bamboo door-plate and Bamboo flooring production strategies is what can make Bamboo so desirable.

Bamboo doorways and Bamboo flooring have now been introduced to the market by the stated Bamboo Investigation and Advancement Company of India, Ltd., that's also normally referred to as BGC. Bamboo doorways and Bamboo floors have lengthy been in Dr. Premalatha's (who can be the founding father of Bamboo World-wide Investing Corporation) list of products that he is most happy with. Bamboo World Buying and selling Company or BGC is led by Dr. Premalatha, who's the only real person from Bamboo Worldwide Investing Company's roster that has had any prior working experience from the manufacture and production of Bamboo products. Bamboo International Investing Company has also introduced a complete line of Bamboo similar products which utilizes Dr. Premalatha's name on them.

Bamboo doorways and Bamboo flooring have demonstrated to generally be very popular throughout the world. With many nations, industries, schools and even households having discover of Bamboo's benefits and marveling at its splendor, Bamboo output has grown remarkably. Bamboo has been when compared to wood mainly because it is much much better than most other woods available nowadays. Bamboo has also shown anti-allergenic Qualities, unlike most other woods, which also will make Bamboo perfect for use in applications such as bedroom Find more info household furniture and toilet vanity units. Bamboo creation is about to grow and broaden fast, so the longer term for Bamboo seems to be as dazzling because the sky.